|

Introduction

On Saab 9000s equipped with air conditioning (and/or climate control) the air

conditioning compressor is driven by an electromagnetic clutch. In normal operation,

the clutch cycles on and off regularly. Over time, however, the clutch wears

and the air gap between the clutch and the driven plate increases to the point

where, under certain circumstances, the magnetic coil can no longer pull the

plate against the clutch. The first sign of failure is that the air conditioning

stops blowing cold when the under-bonnet temperature rises significantly. This

is because the high temperature causes the coil resistance to rise, reducing

the available current and consequently the strength of the magnetic field.

I took the car to an air conditioning technician, thinking there was a problem

with the refrigerant. After an unsuccessful attempt, he finally verified that

there was voltage to the clutch and proved the cause of the problem by tapping

the clutch driven plate with a hammer with the engine running, whereupon the

clutch engaged and the compressor started running. I watched him fix it using

the following procedure. Since I have seen a number of reports of this problem,

I felt it worthwhile to dismantle the clutch again in order to document the

procedure for other Saab owners.

This procedure was performed on the Seiko compressor on my '96 Aero. Some other

models are fitted with a Sanden compressor. While the same principles apply

to the Sanden compressor, certain details may vary. However, after lengthy discussion

with other 9000 owners, it appears that this problem is almost exclusively confined

to the Seiko compressor.

Time required

Around 10 minutes.

Tools required

- 5mm Allen key or hexagon bit.

- Feeler gauge

- Screwdriver to lock the driven plate.

- Thread locking compound.

Procedure

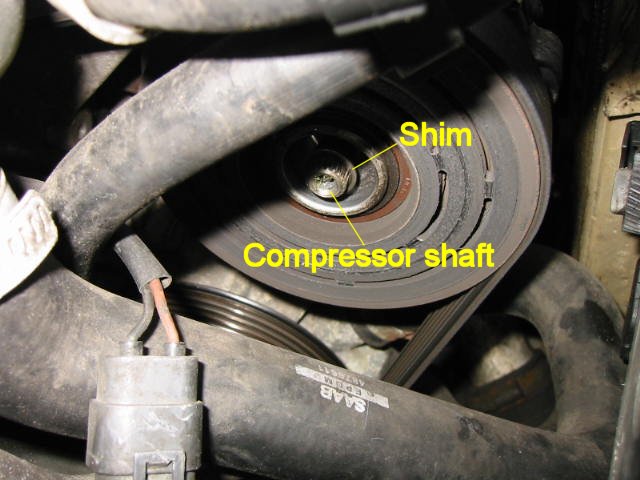

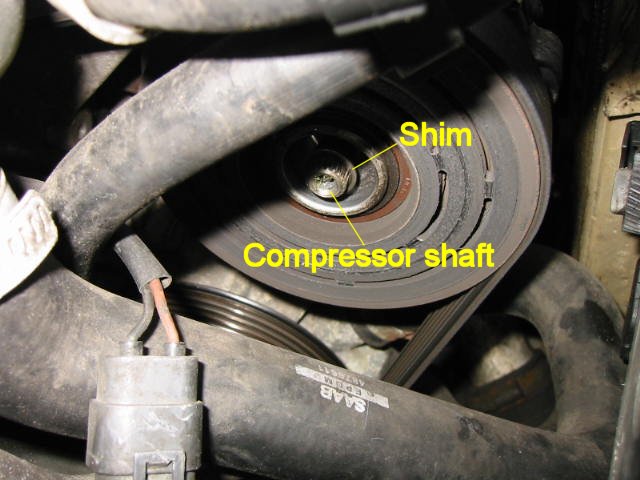

- Locate the compressor clutch as shown below.

- Using a feeler gauge, measure the air gap. It should be between 0.4mm

and 0.8mm (0.016" and 0.031")

for the Sanden compressor and between 0.3mm and

0.6mm (0.012" and 0.024")

for the Seiko compressor. If it is too large, adjust it by following the procedure

below.

- Using a 5mm Allen key or hexagon bit, unscrew the central retaining screw.

Use a screwdriver to stop the driven plate (and compressor shaft) from turning.

Remove the screw and its washer.

- Carefully remove the clutch driven plate, taking great care not to lose

the shims underneath - on my car, the shim was stuck to the plate and fell

into the engine bay as I withdrew the plate. There was only one shim, but

since the gap on my clutch had already been reduced, I know that at least

one shim had already been removed. The driven plate and shim can be seen below.

The wear on the plate after almost 150,000 miles is quite apparent.

- Remove one or more shims to achieve the required gap. Refit the remaining

shim(s) onto the compressor shaft. On the Seiko compressor, each shim is approximately

0.5mm thick.

- Refit the driven plate. I found that the retaining screw had had thread

locking compound applied, so I applied fresh threadlock. Refit the screw and

washer and, using the screwdriver to stop the driven plate from turning, tighten

the screw. I don't have a torque figure.

- Re-check that the air gap is now within specification.

|