|

Introduction

The handbrake on the Saab 9000 is a mechanical, cable-operated type,

acting on the rear calipers. Two cables are used, each running from

the handbrake lever in the cabin to one of the rear calipers. Adjustment

of the handbrake depends both on the rear caliper adjustment and on

the adjustment of the two cables. In almost every case, the reason adjustment

is required is because of excess travel at the handbrake lever.

A handbrake cable that is too loose will also give rise to too much

travel in the brake pedal and reduced braking force at the respective

caliper.

Time required

This procedure took about 20 minutes per side. As usual, double this

for the first side if you haven't done it before.

Tools required

As usual, I assume some basic tools, such as a jack, axle stands, socket

set, etc. However I do not assume you will already have all the necessary

metric socket and spanner sizes, especially if you are in the USA. Here

is a list so you can make sure you have all the necessary sizes before

you start.

- T-25 Torx® driver

- 4mm hexagon bit or Allen key

- 14mm socket or spanner

- 17mm socket

Procedure

Perform this procedure on th right-hand wheel first, then repeat for

the left-hand wheel.

- Jack up the rear of the car and place it on axle stands. If you

are not sure where you can safely place the jack and axle stands on

a 9000, go here for more information.

- Remove the roadwheel.

- If the handbrake is applied, release it.

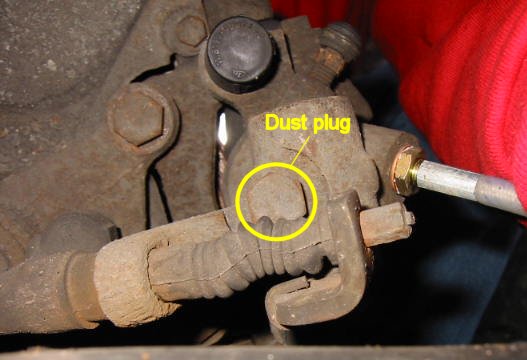

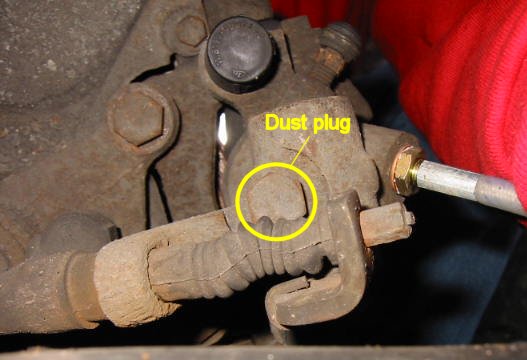

- Remove the dust plug on the rear of the caliper (near the handbrake

cable) using a 14mm spanner. This will reveal a 4mm Allen screw. (Photos

taken from within the wheel well).

- Using a 4mm Allen key or hexagon bit, locate the screw under the

dust cover and rotate it move the pads against the disc, then turn

anticlockwise a quarter turn or until the disc can just be moved by

hand.

- Refit the dust plug.

- Remove the pads. Girling pads simply slide out, as does the outboard

ATE pad. The inboard ATE pad clips into the piston. Pull it directly

out of the piston to remove.

- If you wish to remove and replace the brake disc (rotor), this is

the time to do it. Click here for the

procedure.

- Fit the new pads as a straightforward reversal

of removal. My ATE pads came with a spring clip for the inboard pad

and a self-adhesive pad on the outboard pad. If you have a self-adhesive

pad backing, remove the backing paper before installation. If not,

smear the backing plate of the outboard pad (and inboard pad for Girling

calipers) with copper grease to help suppress any brake squeal.

- Reposition the caliper and, for ATE calipers, refit the spring clip.

- Smear the sliding pin(s) with copper grease and refit. Tighten them

snugly.

- Refit the plastic plugs.

- Refit the roadwheel.

- Lower the car.

- Torque the roadwheel bolts to 120Nm

(90lbft).

- Press the brake pedal repeatedly to move the pads back onto the

discs. If you don't do this, the brakes won't work the first time

you use them (and there may never be a second time!)

- Check the fluid level in the master cylinder reservoir. Top it up

to MAX if necessary.

- The brakes will not perform well for the first hundred miles or

so until the pads bed in. This seems to take longer if the discs are

new as well. With new discs and pads, be especially careful

for the first few miles. The performance of mine after doing all four

wheels was pathetic for a few miles. I have since adopted the practice

of doing the front discs and pads, driving for a few miles to get

them working, then doing the rear pads and discs and going for another

test drive. This is a bit safer and less harrowing.

|